The natural ingredient aloe vera gel stands among the most popular natural components utilized in cosmetic, skincare, food supplement, and health product development. Homemade aloe gel production remains simple but commercial businesses must conduct extensive regulatory procedures to produce stable and safe products. The following article details the complete comprehensive production process of commercial aloe vera gel.

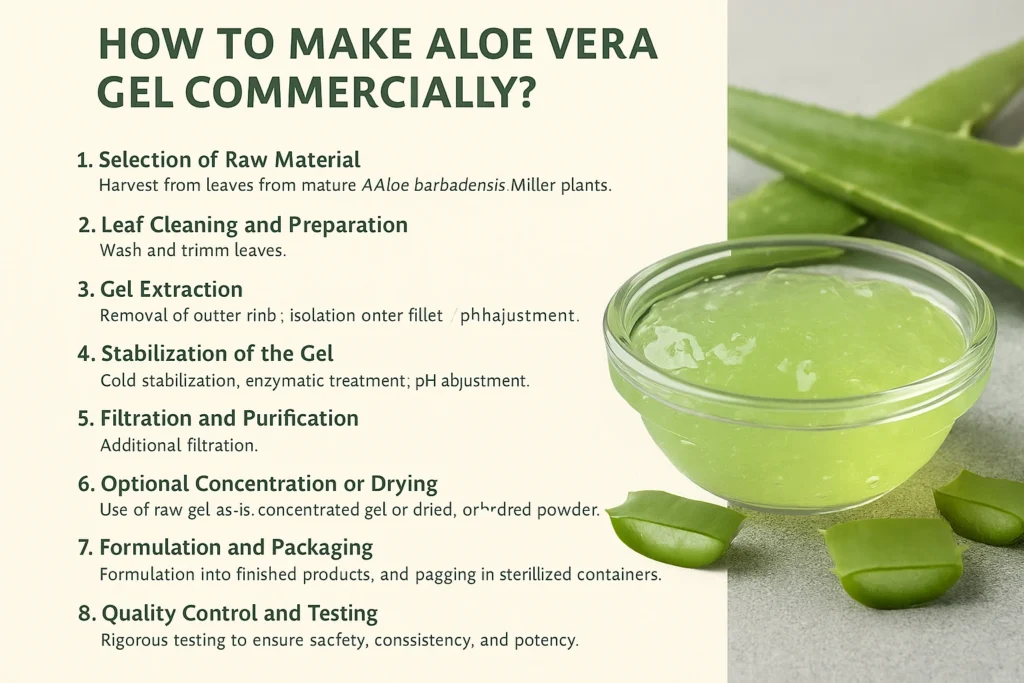

1. Selection of Raw Material

The commercial production starts with selecting Aloe barbadensis Miller plants because they contain high levels of beneficial compounds. Commercial harvesting of leaves happens from established plants which exceed three years of age because this age leads to maximum compound levels including enzymes, vitamins and polysaccharides.

Key Considerations:

The selection criteria for leaves require them to have thick dimensions along with healthy conditions that show no signs of physical damage or disease.

Human labor performs the harvesting operation which helps prevent damage from knuckle injuries and maintains structural integrity.

2. Leaf Cleaning and Preparation

Leaf washing represents a necessary step which removes both soil, pesticides along with microbial contaminants that exist on harvested leaves. Washing the leaves at this point represents a necessary step toward hygiene requirements while blocking future deterioration.

Processes include:

High-pressure water rinsing

Antibacterial rinsing (e.g., food-grade chlorine or ozone water)

A procedure of trimming edges removes both thorns and discolored parts from the fruit.

3. Gel Extraction

There are two major approaches to extracting the gel:

a. Inner Leaf Fillet Extraction

This is the most common method for high-quality commercial gel. The outer green rind is carefully removed to isolate the clear inner fillet.

b. Whole Leaf Extraction

In some cases, the entire leaf is ground and then filtered to remove unwanted substances like aloin. This method yields a higher volume but requires additional purification steps.

4. Stabilization of the Gel

The biological activity in fresh aloe vera gel deteriorates promptly because it has a short shelf life and rapid rate of oxidation. The aloe vera gel requires instantaneous stabilization immediately after extraction process. Different methods exist for protecting biological activity in order to extend product longevity.

a. Cold Stabilization

The gel receives preservation through temperature control at cold levels together with gentle preservation additives which block microbial growth yet preserve natural properties.

b. Enzymatic Treatment

A particular group of enzymes breaks down undesirable compounds as they enhance product clarity while maintaining consistency.

c. pH Adjustment

Manufacturers adjust the pH value to within 4.5–5.5 range to provide a comparable environment to skin and enhance product stability and compatibility.

5. Filtration and Purification

Cellulose gel stabilization allows filtration to eliminate fibers with suspended solids from the mixture. Advanced filtration systems such as microfiltration along with activated carbon treatment perform the separation processes.

Benefits:

Enhanced transparency

Better texture

The extraction process removes both aloin and remaining anthraquinones from the aloe vera products.

6. Optional Concentration or Drying

Depending on the final application, the gel can be:

Used as-is in its raw gel form

Concentrated to reduce water content

Freeze-dried or spray-dried to create powder form for cosmetics and supplements

7. Formulation and Packaging

The purified aloe vera gel exists in bulk form or gets included in finished products such as moisturizing gels beverages and creams. The product goes through sterilization before packaging in controlled spaces inside sterile containers.

Packaging Considerations:

UV-protected bottles or sachets to prevent degradation from light

Vacuum-sealed or nitrogen-filled to avoid oxidation

8. Quality Control and Testing

Each batch of aloe vera gel undergoes rigorous testing to ensure safety, consistency, and potency.

Standard Tests Include:

Microbial analysis

Polysaccharide content (e.g., acemannan)

pH and viscosity testing

Absence of harmful residues

Third-party certifications (such as ISO, HACCP, Kosher, and organic standards) may be required for certain markets.

9. Applications of Commercial Aloe Vera Gel

Once processed, the gel is used across multiple sectors:

Skincare: Hydrating creams, after-sun gels, serums

Health foods: Functional beverages, detox drinks

Pharmaceuticals: Topical wound care, oral supplements

If you are looking for premium-grade aloe vera extract powder, please feel free to contact us at [email protected].

References

Sánchez-Machado, D.I., López-Cervantes, J., & Sendón, R. (2020). Aloe vera: Properties and processing for food and pharmaceutical industries—A review. Journal of Food Science and Technology, 57(6), 2251–2261. https://doi.org/10.1007/s13197-019-04251-9

Surjushe, A., Vasani, R., & Saple, D.G. (2022). Aloe vera: A Short Review. Indian Journal of Dermatology, 67(2), 123–126. https://doi.org/10.4103/ijd.IJD_72_21

Rodrigues, D., & Pereira, L. (2021). Commercial Applications of Aloe vera Gel in the Food and Cosmetic Industry. Industrial Crops and Products, 162, 113229. https://doi.org/10.1016/j.indcrop.2020.113229